New B2B commerce study

Download nowReliably detecting tiny inclusions

Quality assurance in metal production

Sheet metal with manufacturing defects can rarely be further processed. The automotive industry in particular cannot continue working with a defective intermediate product due to its high requirements. Cutting to a smaller size can only be sold by the manufacturer to a very limited customer base and means a loss of margin. We approached the problem with a specially developed neural network architecture.

small inclusions are detected

detection accuracy if non-metallic inclusions (NMI) are present

Spoilers:

oxygen, nitrogen and sulfur

Scratches are not yet showstoppers at this stage of production. Non-metallic inclusions (NMI) are problematic because they permanently affect product properties. Oxygen, nitrogen and sulfur may become deposited in the alloy as oxides, nitrides and sulfides.

Challenge

Detection of very small troublemakers

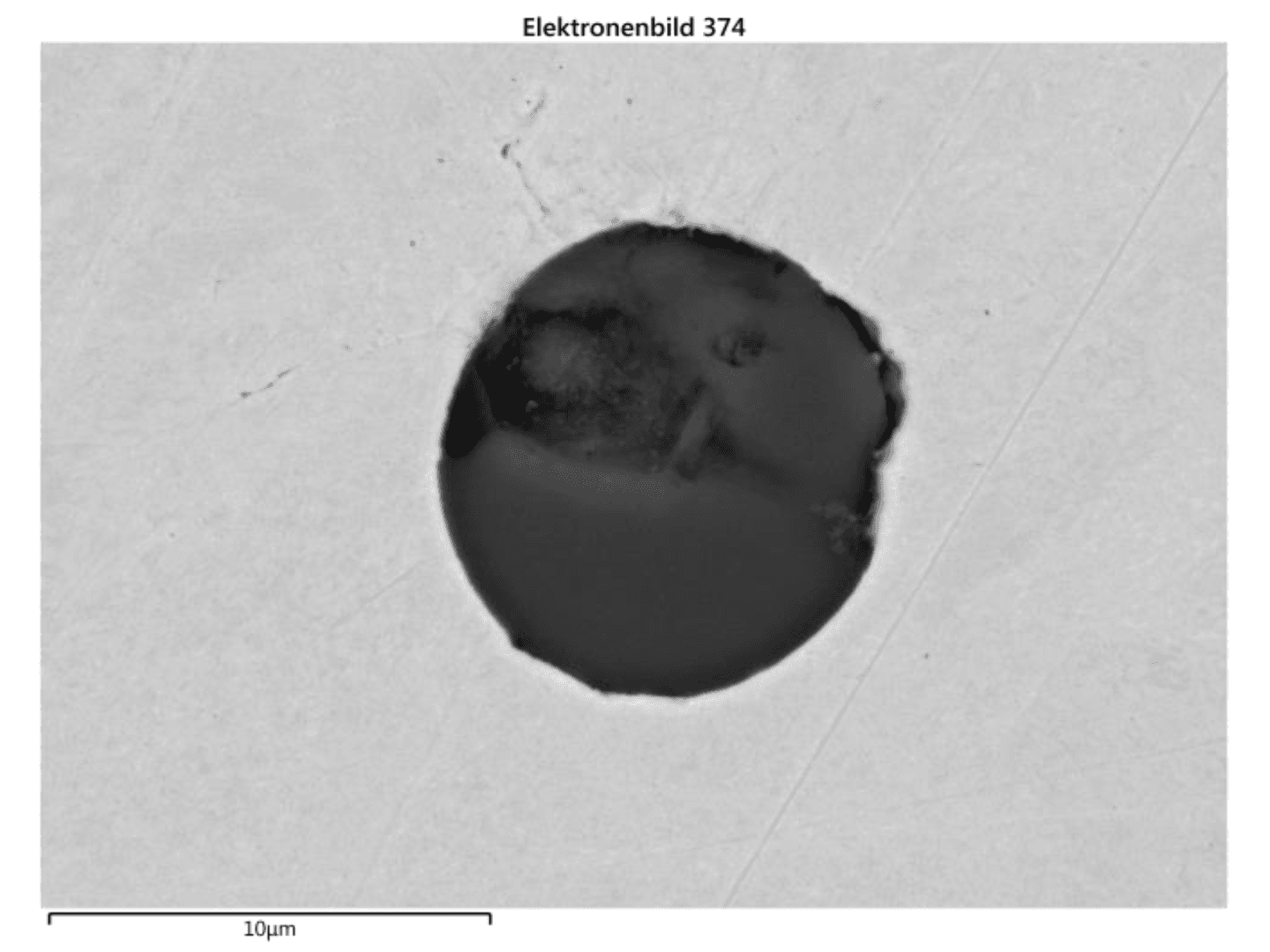

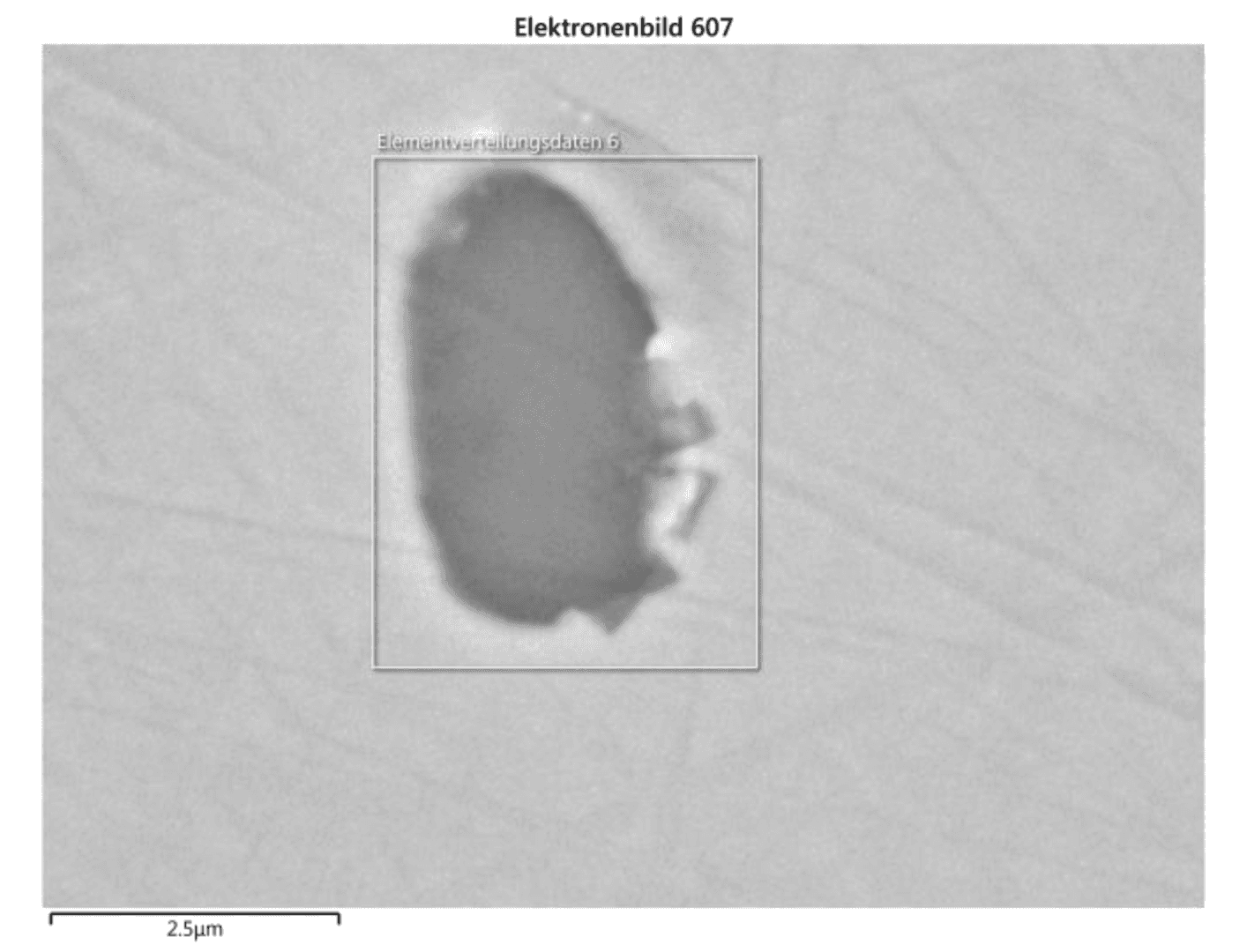

If this deposition has occurred, it is important to find out how severe the defect really is. To do this, we work with image classification. Oxide, for example, can be made out as a dark round dot under an electron microscope, while sulfide is much brighter. However, this optical recognition is time-consuming. And even an experienced laboratory worker cannot detect these micrometer-sized inclusions without error. Chemical analysis is reliable, but far too expensive.

Solution

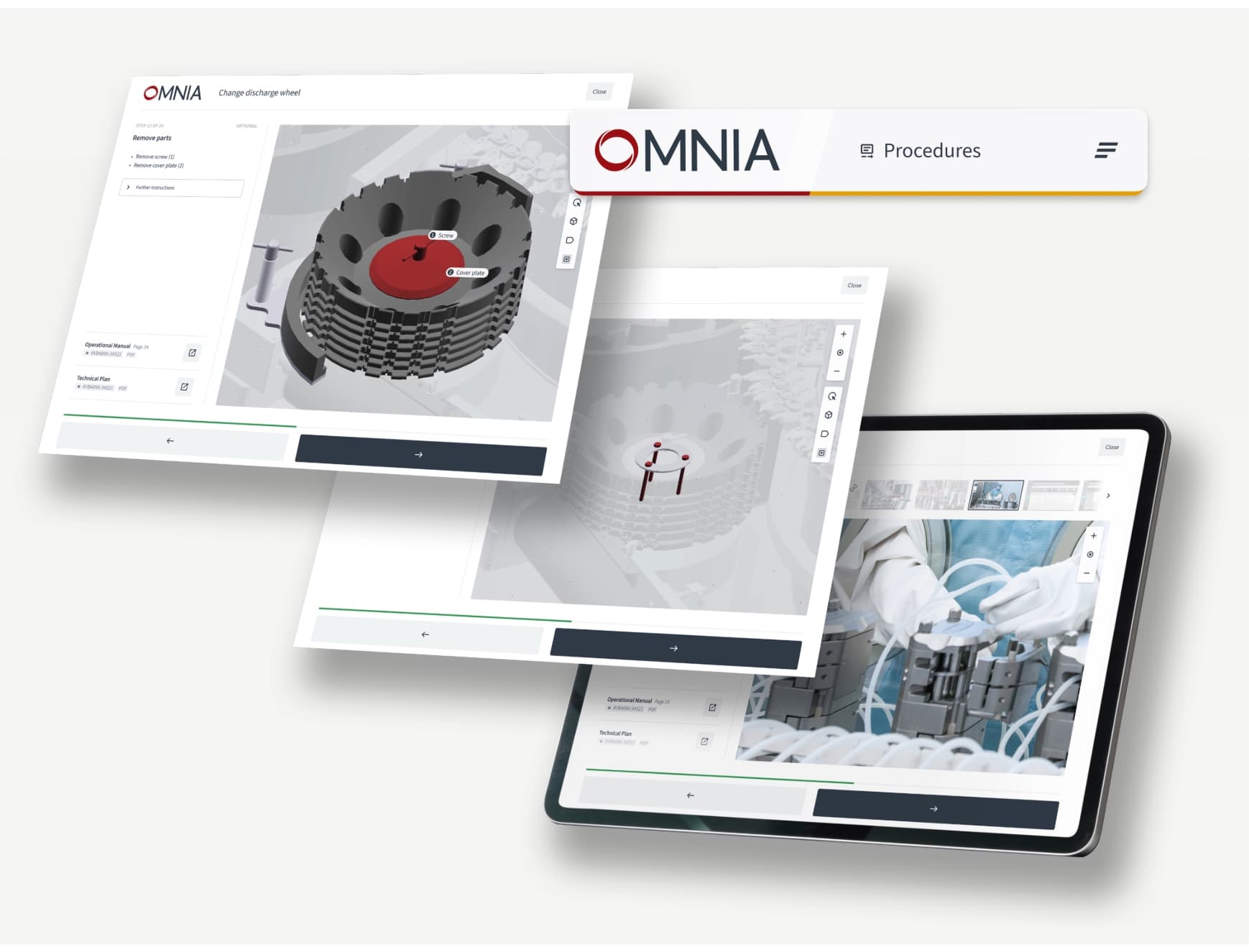

Specially developed neural network architecture

For efficient automation, we work with a multi-class image classification model to identify whether it is a relevant material inclusion and what type of defect it is. The multi-stage approach is useful for efficiency reasons, so that full power does not have to be applied as soon as the irregularity is detected, but only when it is classified.

In the first step, any irregularity on the sheet surface is detected. Only in the second step is the image classified more precisely: Is it a scratch, or a pore that does not affect stability, or a dreaded non-metallic inclusion (NMI)?

Since the types of neural networks (Convolutional Neural Networks) widely used in computer vision are not designed for these tiny phenomena, we have, among other things, designed our own network architecture to process image sizes far below one micrometer.

The CD Laboratory

The CD Laboratory for Inclusion Metallurgy in Advanced Steelmaking is a research unit of the Christian Doppler Research Society. It is headed by Assoc.Prof. DI Dr. Susanne Michelic from the Chair of Ferrous Metallurgy at the University of Leoben. In the research period until August 2028, definitions and recognition accuracies of non-metallic inclusions (NMI) will be refined. The foundation for the use of machine learning and AI for this challenging project was laid with Cloudflight.

Christian Doppler (1803-1853) was an Austrian mathematician and physicist. He is known for the Doppler effect named after him.