New B2B commerce study

Download nowCloud migration from on-premise to cloud native

Maximum Flexibility and Security thanks to cloud-native architecture

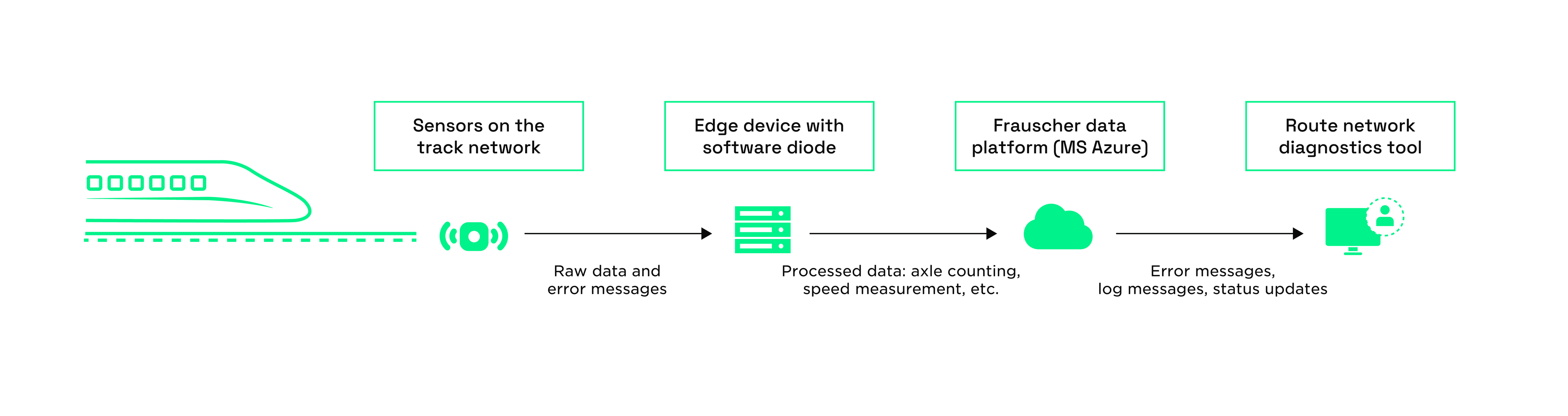

Wheel sensors and axle counters play a crucial role in ensuring safe and reliable railway operations, enabling key applications like wheel detection and track vacancy detection. The wheel sensors precisely detect in which section of the track a train is located, ensuring that signal systems and interlockings can correctly perform their safety-critical functions.

The previous approach to processing diagnostic information was based on a local log computer, which stored all relevant data and made it available for on-site analysis within the closed network. However, with this on-premises solution, it was necessary to carry out both the evaluation of diagnostics data and updates on-site. Therefore, an IoT data platform should be developed that allowed central data storage for scalable applications in diagnostics and maintenance.

The challenge

Migration of on-premises systems to a cloud environment

In order to develop the desired IoT data platform, the existing on-premises system had to be migrated to a highly secure cloud environment. This migration not only had to seamlessly integrate the existing functionality, but also take into account additional requirements of the railroad industry – including extremely high availability and stringent security standards.

The idea

Maximum flexibility and security thanks to cloud-native architecture

Frauscher should benefit from significantly increased security, scalability, location-independent accessibility, and continuous update capability. A cloud-native approach was therefore chosen, in which applications are handled in the form of individual, container-based microservices. This not only enables a flexible and scalable architecture but also improves the system's responsiveness to changing requirements and loads.

Thanks to this architecture, monitoring error messages and warnings, as well as the maintenance needs of sensors, can be detected early. In addition, the cloud application allows the integration of predictive maintenance, which detects potential weak points before they lead to failures. This minimizes unplanned maintenance and makes a decisive contribution to increasing uptime and safety.

The solution

IoT data platform reduces costs and optimizes performance

As part of the migration to a cloud-native approach, the backend was completely modernized and the complex IoT architecture requirements were successfully transferred to the new platform. This changeover enabled a significant reduction in support times and a drastic shortening of update and release cycles. In addition, the globally available database allows the use of machine learning models to implement predictive maintenance, which detects potential problems at an early stage and prevents failures.

This has enabled Frauscher to achieve the following results:

- Massive data processing: 100+ million Azure IoT messages processed daily

- Real-time data-driven support

- Global implementation: 18 successful production installations worldwide

Frauscher Sensortechnik GmbH

Frauscher Sensortechnik GmbH offers innovative solutions for the individual requirements of customers worldwide in the field of axle counting and wheel detection. The company was founded in 1987 by Josef Frauscher. After several decades of successful sensor development, it went into international expansion starting in 2010. Since 2019, Frauscher has been part of the Delachaux Group.

Frauscher Sensortechnik strives to make it easier for system integrators and rail operators to access information needed to operate and monitor their infrastructure.

With a worldwide network of locations and partners, the company also guarantees a strong supply chain and optimal customer support around the globe.