New B2B commerce study

Download nowDigital precision drilling for small craft businesses

With the EASYSTICK, accurate dowel and screw holes can be made without CNC and without CAD, even for small quantities.

Worthwhile even for single pieces

Julius Blum GmbH from Vorarlberg is one of the world’s leading manufacturers of furniture fittings. In addition to hinge and rail systems, Blum also offers its customers processing aids for furniture production. From carpenters to furniture factories, customers in 120 countries work with Blum products and solutions.

Small cabinetmakers produce furniture in small quantities and do not use CAD modeling or CNC milling. Calculating and drilling carcasses manually can take a long time and introduce errors. So that these companies don’t have to manually re-measure every drilled hole for drawers and cabinets, there’s EASYSTICK. The automated stop system for drilling machines is even worthwhile for single pieces.

We have developed the EASYSTICK software and optimized the functions and simple operation via touchscreen together with our customer Blum.

The challenge

Need-based computing power in the embedded system

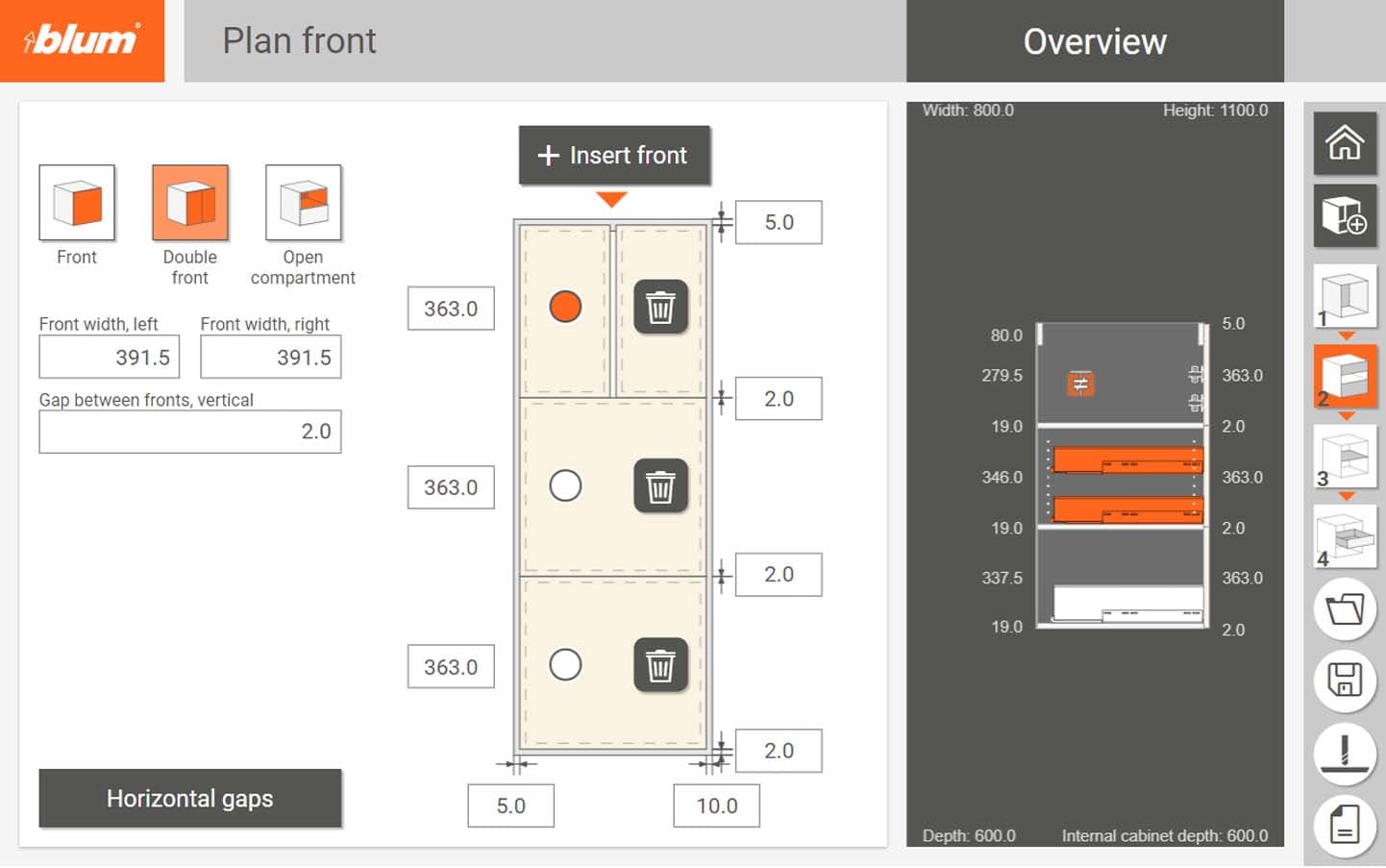

The EASYSTICK queries all numbers and dimensions on the user interface using clear graphics - from the number of doors or drawers to the thickness of the interior walls. The holes for dowels and screws are to be drilled quickly and efficiently. In order to calculate the sequence, EASYSTICK draws on extensive Blum catalog data: A simple database query is not enough here. This is because the catalog contains all Blum products, as well as the set of rules for determining the dimensions of the fittings and construction holes. These are applied in the form of formulas and logical calculations. These complex operations have to be implemented in the embedded system. The computing power in this system is severely limited.

To ensure that the EASYSTICK nevertheless determines the drilling sequence quickly and correctly, we took the performance and peculiarities of the executing drilling machine into account at every stage of development. The algorithms were continuously tested on the machine and intermediate steps were inserted for time optimization.

The solution

"Lay out the board, drill, done.”

Furniture hardware manufacturer Blum can promise its customers effortless processing of its products with a highly specialized solution: After the drilling points have been digitally determined, the EASYSTICK indicates the correct positions, and then it's just a matter of "lay out the board, drill, done!"

The qualified cooperation between Blum and us goes even further: on the way to the finished piece of furniture, carpenters now have 20 languages at their disposal on the EASYSTICK. It is also possible to enter values in the Anglo-American units of measurement inches and feet. A new function helps with the simple drilling of cabinet fronts. Customized updates are possible in encrypted form, and the new online service provides access to planning data from other Blum configurators.

We coach our colleagues in the development process so that Blum developers can modify the software themselves if necessary.

Our service goes beyond mere implementation and, as always, extends exactly as far as there is a need. We are happy to help you!

Julius Blum GmbH

The name Blum stands for innovative products, dedicated employees and international market presence. On March 1, 1952, Julius Blum founded his company and manufactured his first product: hoof studs for horses. Today, Blum is one of the world’s leading manufacturers of furniture fittings.