New B2B commerce study

Download nowQuality Assurance

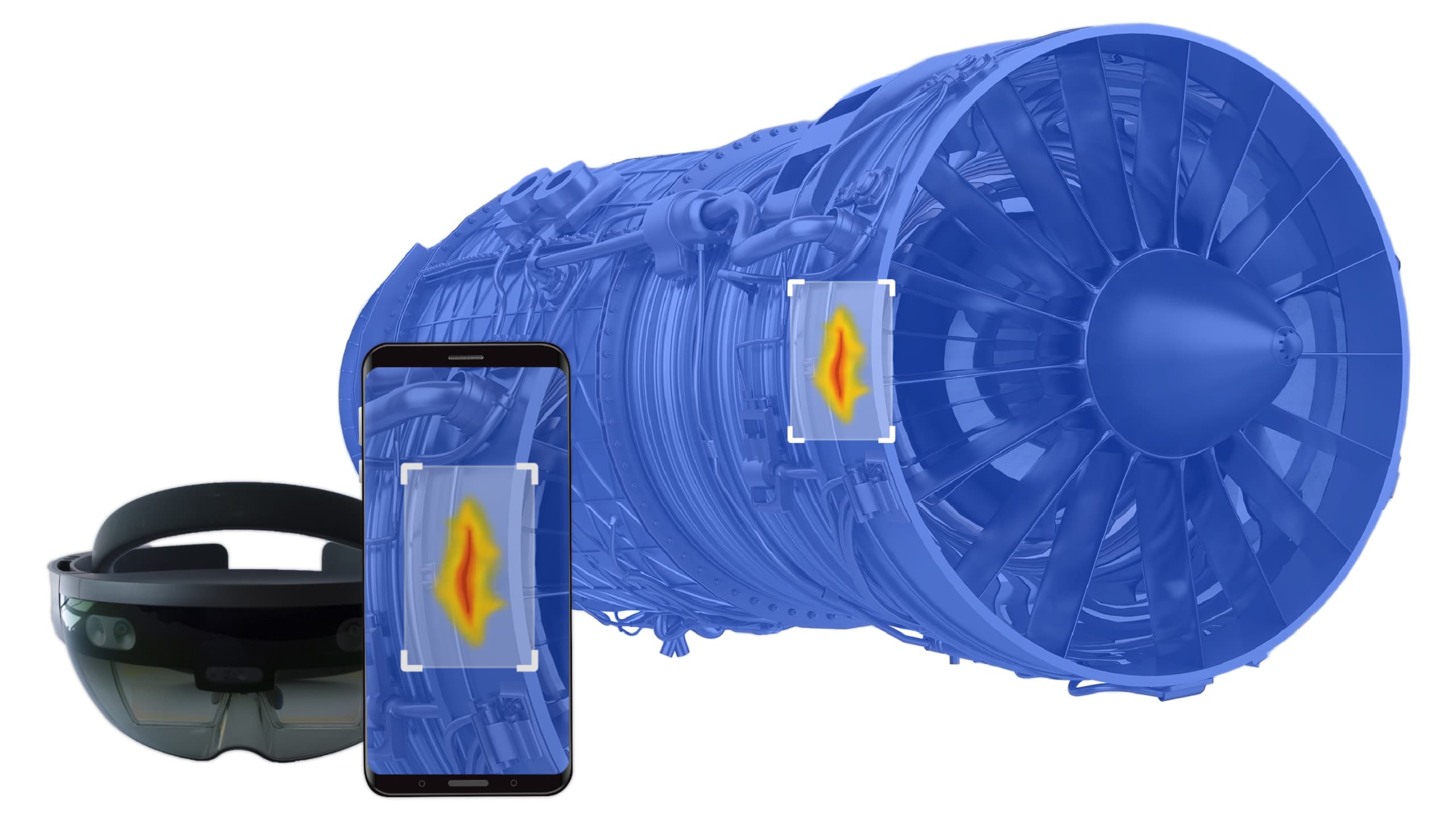

Non-destructive Testing with Augmented Reality

Intuitive visualization of non-destructive testing results in quality assurance. In recent years, the development of affordable and reliable virtual and augmented reality platforms has gained significant traction, especially from the consumer electronics industry.

Inspecting in Augmented Reality

The idea of this research project is to utilize these relatively low-cost platforms with the imaging capabilities of modern NDT measurement techniques to enable an intuitive and accurate inspection workflow.

We developed a system that makes it easy to visualize NDT data using AR devices to simplify and accelerate processes for the operator.

The challenge

High standards and cumbersome processes

The ever-growing need for Non-Destructive Testing – especially in industries striving for „zero failure production“ – has led to an abundance of high resolution, multidimensional scan data sets. While these data sets enable an unprecedented level of quality of the component to be inspected, they don’t come without challenges:

Visualizing and inspecting these data sets is a time-consuming and largely non-intuitive process – with the biggest challenge being the registration of the scan data on the real-world component. Here’s where we entered the equation.

The solution

From data to images to your tested components

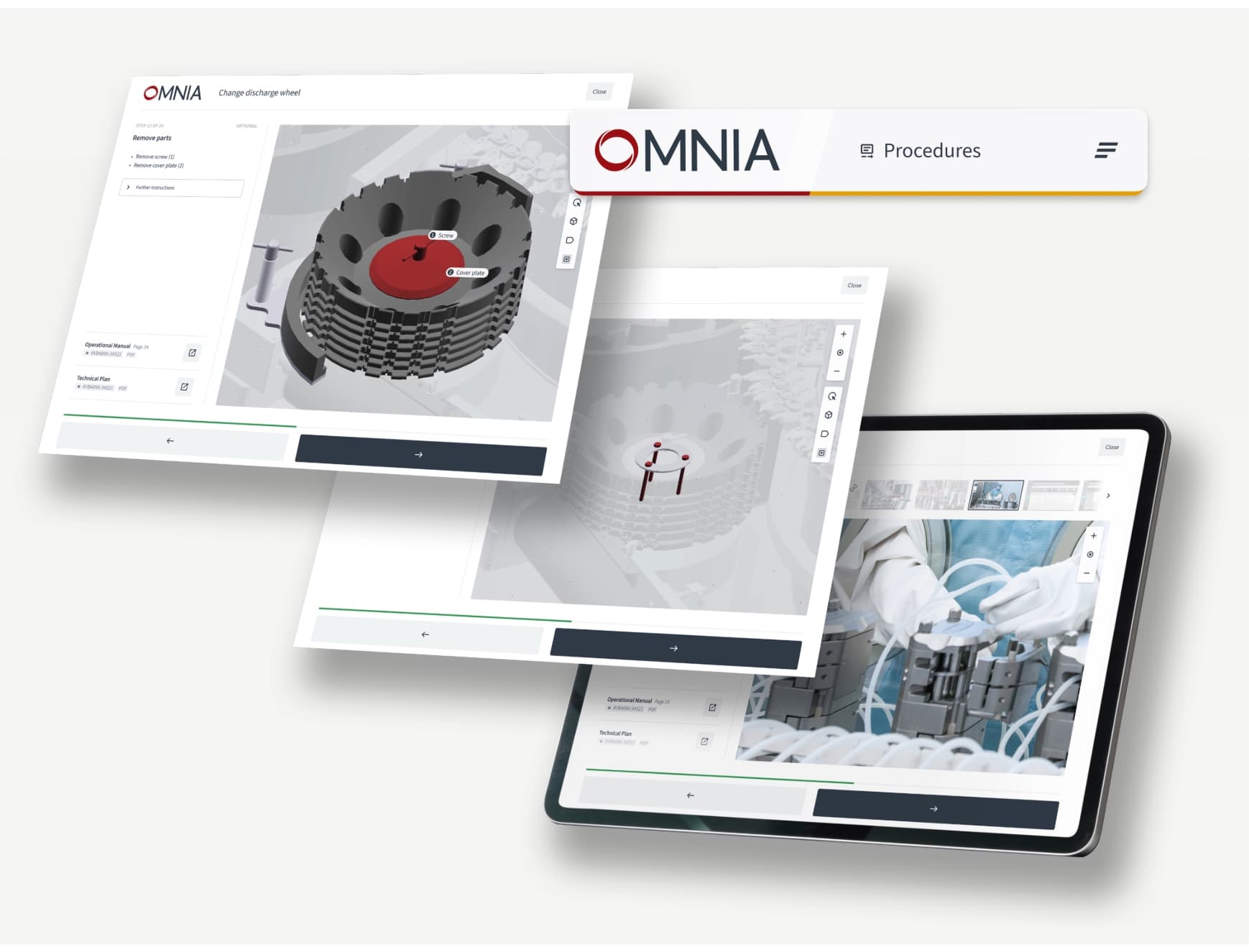

Together with our partner ReceNDT, one of the leading research companies in the field of non-destructive testing, we have developed a system that enables the user to project measured test results directly onto the component they were taken from.

For this purpose, we defined a process that clearly specifies how the measurement data is to be prepared in order to enable seamless interaction between the virtual data and the real component. The system itself relies on Augmented Reality technology that visualizes the data.

This entails that the system is always ready to adapt to the ever-developing field of Augmented Reality, where the concept of “state-of-the-art” is far from constant and unchanging.

By mapping NDT scan results onto the tested component, co-registration can be achieved. This allows the overlay of location-dependent measurement data on the component, allowing the operator of such a system to quickly inspect parts of the component both physically and through the scan dataset.

The system transforms scan data into color-coded images which can then be projected onto the real component as an overlay, thus simplifying the operator’s perception: this does not only accelerate the inspection process, but it also enables the detection of otherwise easy-to-overlook defects.

To find out more about this project, get in touch with us! We can help you discover how you can either leverage the use of your data with AR, or accelerate your own quality-assurance processes.

ReceNDT

ReceNDT coordinated this research project. The measurement of 3D freeform objects and the generation of the NDT results that can be used by the software.